REPAIR, RETROFITTING AND REHABILITATION

Rehabilitation and retrofitting reduces the vulnerability of damage to the existing structure during a modification according to the functional of other needs. It aims to strengthening the requirements of the current codes. The retrofitting benefits in terms of reduction in the loss of lives and damage of the essential facilities and functional continuity of the life line structures. For an existing structure of good condition, the cost of retrofitting tends to b smaller than the replacement cost. Thus the retrofitting of structures is an essential component of long term functional requirements and disaster mitigation. Repair, retrofitting and rehabilitation of existing structure have become a large part of the construction activity nowadays.

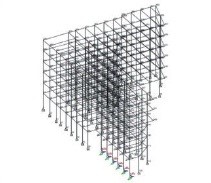

Retrofit Design:

A.J Associates is good in supplying designs for retrofitting of different structures. The Retrofitting design includes changing the configuration of the structures, enhancement of strength, design the additional tools and designing different schemes for seismic compliance for the existing structures.

Dr. MGR Educational and Research Institute:

- In this building, a row of columns of part of the “L” shaped building had to be removes and substituted with steel built-up columns at an offset location for 6 floors (G+5)

- Being an institutional building the work was carried out on war-foot basis and completed within a time frame of 21 days.

- The part of the building was chopped off by using diamond saw equipments.

- The built-up columns were anchored to the RCC beam and bottom RCC floor using chemical anchors. Lateral bracings using rolled structure steel beams were also provided.

- The building was analyzed for its stability before the retrofitting scheme was implemented.

- The theoretical structural modal was built in the structural analysis software and the retrofitting scheme was incorporated.

- The modal was given the loading conditions as per the latest codes and analyzed for its stability.

Structural Strengthening:

Caterpillar Thiruvallur:

- The building was designed for 2 storey (G+1) and later it as decided to built another two floors warranting to strengthen the ground floor structural elements

- All the footing and columns were strengthened. The footing and the column size were enhanced.

- The columns were jacketed with high strength concrete with addition of reinforcement to cater to the new loading system with shear connectors to make the jacketing to act as part of composite section.

Puruvankara Commercial Project:

- This multi-storied commercial building was designed for G+6. But on execution noticed that the peripheral columns are getting distressed and investigation, it was found the exterior columns were under designed.

- The remedy was to enhance the size of the exterior columns with additional reinforcement and high strength concrete for early strength attainment.

- The latest polymer modified concrete mix was used to gain early and high strength to ease the ongoing construction process.

Residential Appartment Project:

- This multi-storied commercial building was designed for G+9. But on execution noticed that the peripheral columns are getting distressed and investigation, it was found the columns were under designed.

- The columns were jacketed with high strength concrete with addition of reinforcement to cater to the new loading system with shear connectors to make the jacketing to act as part of composite section

Foundation Strengthening:

- As the foundation system designed was not sufficient for the revised functional requirement of additional floors, the structural elements were strengthened for this office building.

- The foundation was strengthened by adding additional reinforcements and increasing the size of the footing. The re-bars were added by lock-set principles.

- Necessary shear connectors are fixed with lock-set principle using HILTI chemicals. The shear connectors are fixed to old footings and old columns.

- In addition to the foundation size enhancement, the columns are also jacketed with micro-concrete to a thickness of 75mm on all sides of the columns with additional longitudinal and transcerse reinforcement as required.

Slab Strengthening Work By Structural Steel Fabrication:

- Slabs constructed over columns which transfer point loads to the beam high was not considered in origin design which resulted in excessive deflection and cracking.

- A.J Asscociates has redesigned the structure and a suitable retrofitting scheme was executed which comprised of introduction of built-up steel beam glued to the soffit of the original RCC beam and construction of new RCC columns to support the built-up steel beam.

- The steel built-up beams were braced at required intervals.

Protective Coatings And Water Proofing (Five Layer System):

- Protective coatings are applied over the structural and non structural members to prevent from the external environment like water, thermal variation, chloride attach in the sea-shore area etc.

- As a result of extensive research in field of new materials, polymer products are developed and extensively used for protective coatings. The most versatile coating applied to accommodate thermal variation is Polyurethane product and applied over all RCC and steel surfaces.

- A.J Associates has extensively progressed in the area of after proofing and has so far done about 1 million Sq.ft of water proofing in various projects.

- A.J Associates has expertise in all types of recently developed water proofing technology like membrane water proofing, acrylic, cementitious type and so on.

- The recently developed is layer water proofing incorporating fiber mesh has grain popularity among industrial applications and the method is technically most effective and comparatively economical in long term benefits.

FRP (Fiber Reinforced Polymer Composite):

basic constituents of FRP are fibers such as carbon, aramide, glass, jute and resin matrix. The fibers come in the form of flexible fabric that is saturated in the field and is bonded to substrate, using a specially formulated structural epoxy The fiber/resin composite also manufactured in the form of pre-cured strips for application to the surfaces that are smooth and can handle the relatively rigid strips.

Advantages of using FRPC for Strengthening Requirements:

- Easy to install

- Flexible

- Low cost

- Corrosion proof

- Light weight

- High strength

- Less installation time

- Durable

- Requires minimal access for installation

- Adds significant strength and ductility without adding mass to the structure

- Does not change the original feature of the structure

Carbon Wraping:

- The RCC columns in a residential building provided with lesser quantity of steel erroneously.

- To ensure the confinement and restore the flexural strength, the 300 CFRP as used laterally and longitudinally.

Rebar Grouting :

Drilling machine is used for drilling Holes 8mm to 42mm dia and the maximum depth was upto 1.20mts. For various applications in construction HILTI or Fosroc Chemicals are used for fixing the rebar which ensures the top quality for unequaled service life.

*Note: Pullout testing of rebar is done as per the client requirements*

Wall & Wire Saw Cutting ( Diamond Sawing )

This is suitable for the new construction and old building renovation work. By using the HILTI DLP 32 is heavy duty machines the concrete was cutting into pieces. The large penetration cutting depth was upto 750mm. This machine protects the structural integrity with less vibration.